Overview

I got an opportunity to visit a museum located near a factory that produces apple(and a little paron as well) juice. I took a sneak-peak at the historical, and current process of preparing juice(Swedish: must) from apples.

Context

Around 200 varieties of apples are cultivated in Sweden. The southern, and western parts have massive cultivation of apples, and it is a cultural thing to drink apple cider. The residents who have apple trees in their backyard often collect apples, and take them to a small-scale apple juice factory(Swedish: äppelmusteri). Alcoholic varieties(cider) also are produced.

Process(partial)

Traditional

Apple crushing/mashing

Curated apples are cleaned, and loaded in a sort of grinder to turn them into a pulp.

Pressing

Two persons operate the apple press. One fills the cloth with pressed apples, the other squeezes the remaining juice.

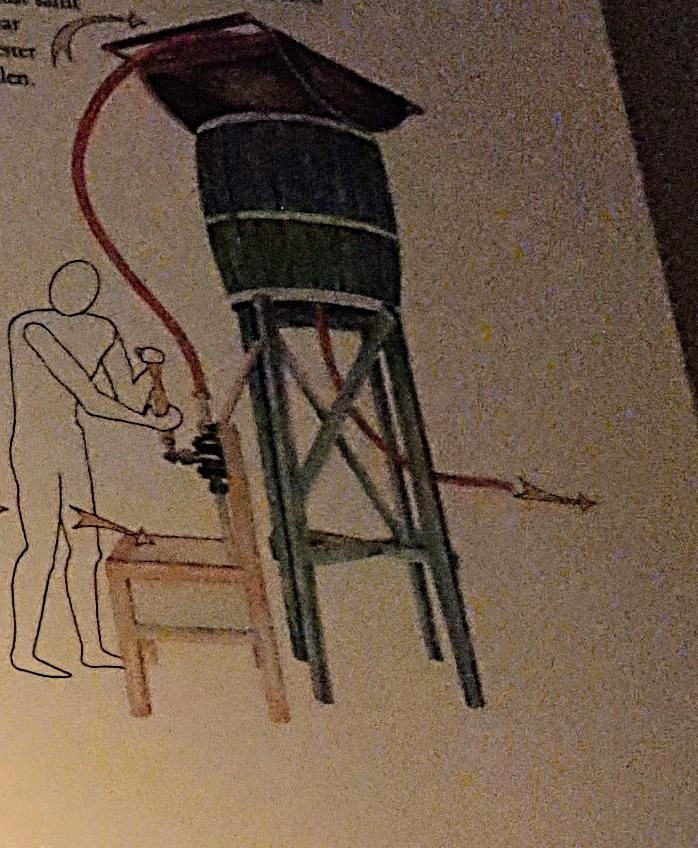

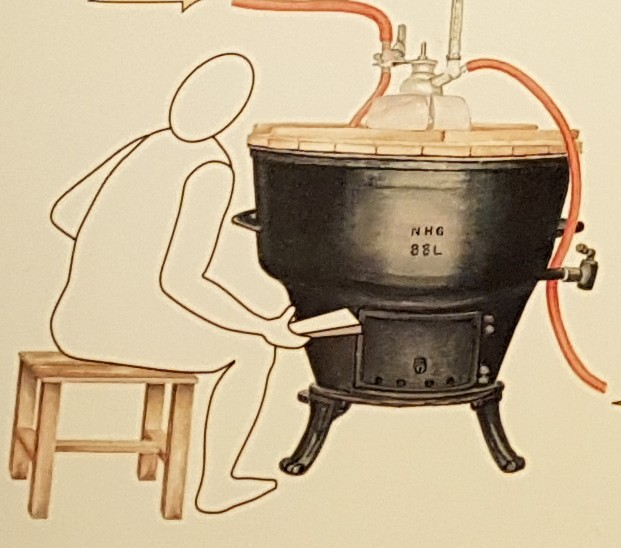

Pasteurizing

The pressed juice is stored in an elevated container, and then is pasteurized. The juice was heated to 85-90 degree celsius, and pasteurization would kill all the yeast, and mould in juice. This ensured a long shelf life. The juice was filled in the bottle at 85° C.

Sterilizing bottles

A laborious and time-consuming part of apple must preparation is the cleaning of bottles. Throughout the 1930s, Rehnvin-type bottles were used, which were purchased from a scrap company packed in jute sacks. The bottles are first soaked in large wooden vats for at least a week outdoors. The bottles are then hand-washed inside and out with warm, effective detergent, and then rinsed for storage.

Before the filling of apple must, the bottles were rinsed with sulphuric acid water, and then the inside of the bottles is rinsed with hot water at the same temperature as the apple must, which at this point is filled into the bottles.

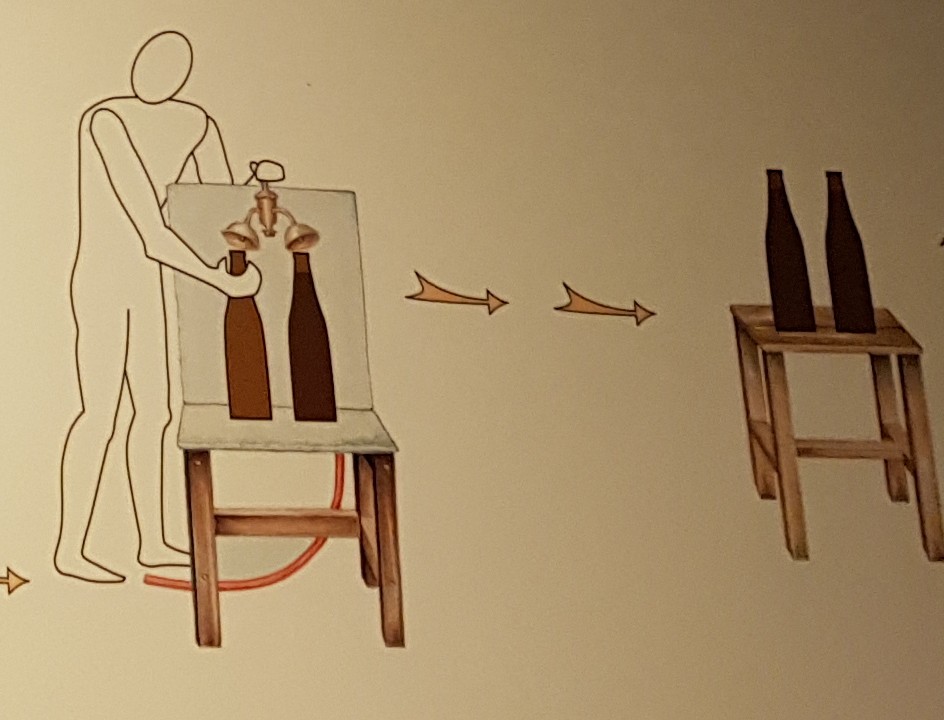

Filling bottles

The apple must was then filled into bottles at a temperature of about 85°C, using a two-pipe tap with filling spouts.

This bottle filler was not one of the worlds highest technical innovations, but compared to the high-tech solutions of today there is one big difference – this old machine was never out of order. The capacity was about 200 bottles per hour. It must have been a risky piece of work to fill up the bottles with 85 °C hot apple juice.

Contemporary

The logic of the contemporary process is almost same as the traditional. Some steps are combined, and with technological advancements, automated machines handle larger volumes.

Apple press

There are two ways to extract the juice of the apple mesh. It can be done either continuously through a “Centristainer” like this, or by batch in a hydraulic press. A Centristainer works both as a centrifuge and a strainer in one. The peel, stem and pips are removed.

Several factors affect the amount of juice that you can extract. It depends among other things of which sort of apples you choose to press, on holding time, temperature and type of equipment (in the best case about 80 %). It is of great importance to take care of the apple mesh. We want to avoid oxygen admixture as far as possible.

Different combinations of these machines are used, depending on which product that is produced. A “Centristainer” has a capacity of 3.000 kg/hour. A Hydraulic press can handle a batch of 4.000 kg/hour.

Pasteurizing

Modern pasteurising units are controlled automatically. You adjust the flow to the properties of the product and control temperatures with electronic regulators. Heating is often done by steam, which warms up a water circuit which finally heats up the product to 90 °C.

On its way out, the hot product heats the cold incoming product. Then it is refrigerated to 10-20 °C. This technique saves up to 90% of the energy consumption.

The most frequently used model is the plate heat exchanger. Everything in stainless steel. The benefit from a continuous process is that both heating and refrigerating is done extremely fast. It is only a matter of seconds. The purpose of pasteurising is to kill all noxious microorganisms like yeast and mould fungus or pathogen bacterias.

Examples of pasteurised products are: juice, milk, soup, fruit-purée, still drinks, lemonade, cider etc.

Filling

The idea is to seal the packing on the production level without contact of oxygen. The pasteurised product is filled in a “tube” of packing material which has been sterilised in the filling machine. This “tube” which constantly is filled with product, is sealed and cut, all in one moment, be fore the packing finally is formed into a Tetra Brik Aseptic pack. This product is now what you can call aseptic and it can be kept unopened in room temperature.

The Tetra Brik Aseptic filling machines of today can manage up to 15.000 packs/hour. They are available for packs from 0,2 litres up to 1,5 litres.

The packing consists of five different coatings

1. Polythene plastic

2 Cardboard with print

3. Polythene plastic

4. Aluminium foil (as an oxygen barrier)

5. Polythene plastic

Final Product

There is wide range of products that an apple juice factory can create, following are just two of them: